Exhibition

Long Term Grain Storage: How Long Can Grains Be Stored? (Wheat, Corn & Quinoa)

Whether you grow your grains or buy them in bulk, the correct long term grain …

Ceramic Custom High Wear resistance Talc Porcelain Electrical Insulator Steatite Plate Parts

Product Description

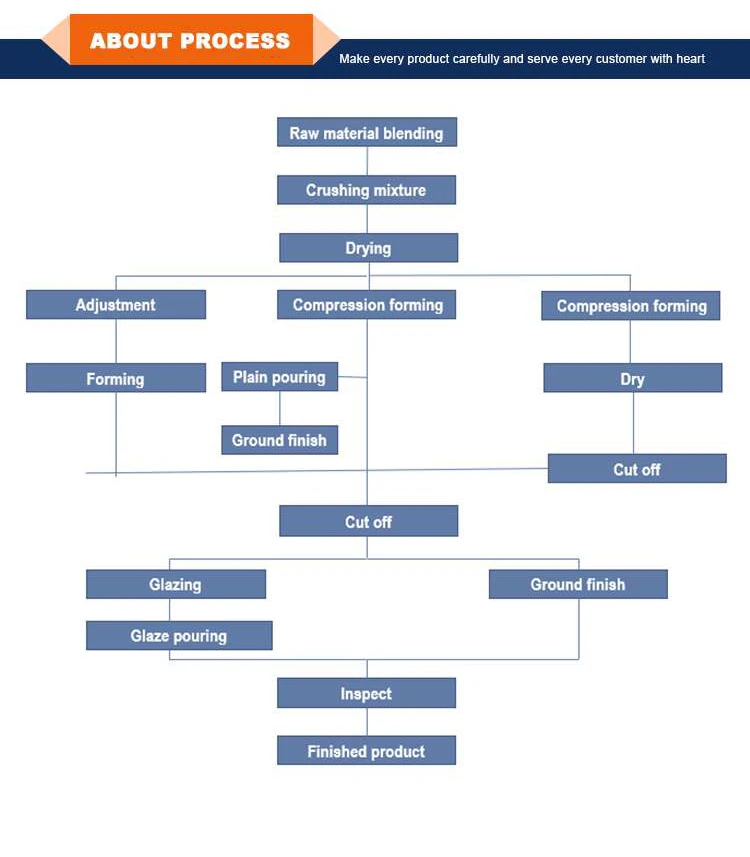

Steatite is a high frequency and ultrahigh frequency porcelain insulation material. The product is processed by hot die casting molding, dry pressure powder molding, isostatic pressure molding, injection moldingand other processes

Application in electronic appliances, mechanical sealing, petrochemical, automobile zero price, to the sample can be customized,according to the product data quotation

Material Advantages:

1) Good insulation performance and high temperature resistance

2) Low dielectric constant and Great mechanical strength

3) High strength 4) High air tightness

5) High chemical stability

6) High corrosion resistance

7) High heat resistance

8) Low thermal conductivity and thermal expansion

9) Light weight, Long performance life, etc.

1) Good insulation performance and high temperature resistance

2) Low dielectric constant and Great mechanical strength

3) High strength 4) High air tightness

5) High chemical stability

6) High corrosion resistance

7) High heat resistance

8) Low thermal conductivity and thermal expansion

9) Light weight, Long performance life, etc.

Material data:

Properties | Units | Steatite Ceramic | Cordierite Ceramic | Mullite Ceramic | 95% Al₂O₃ | 99% Al₂O₃ | Zirconia Ceramic | Silicon Nitride |

Colour | White | Yellow | White | White | Ivory | White | Grey | |

Density | g/cm3 | 2.7 | 1.9 | 2.6 | 3.5 | 3.85 | 6 | 3.2 |

Flexural Strength | Mpa | 140 | 30 | 120 | 280 | 340 | 1150 | 600 |

Compressive Strength | MPa | 900 | 350 | 500 | 2100 | 2200 | 2500 | 2500 |

Max Use Temperature | °C | 1000 | 1200 | 1300 | 1400 | 1650 | 1500 | 1800 |

Thermal Condutivity | W(m.K) | 2~3 | 1.3~1.8 | 2~6 | 16~28 | 19~30 | 2.5 | 20 |

Thermal Expansion Cofficient | 10-6/°C | 7 ~ 9 | 1.5~3.5 | 5~6 | 6.5~7.5 | 6~8 | 8~10 | 3~4 |

ThermalShock Resistance | △TC | 100 | 300 | 150 | 140 | 150 | 250 | 600 |

Specific Heat | J/kg.K | 850 | 800 | 900 | 950 | 950 | 500 | 500 |

Dielectric Strength | KV/mm | 20 | — | 30 | 12 | 10 | 5 | 20 |

Dielectric Constant | Er | 6 | — | 8 | 9 | 9 | 12 | 6 |

Related Products

Company Profile

Products Description

Certifications

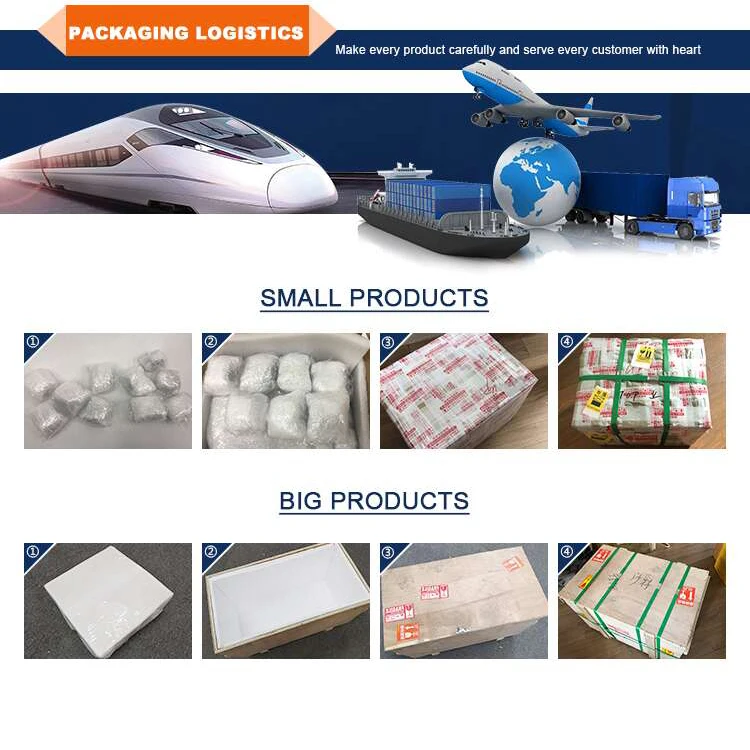

Way of shipping

Our Advantages

FAQ

Q1: How can know your quality?

We can send you samples or sample material for you to check or test.Let our physical samples speak loudly.

Q2:Are these samples free of charge?

Some standard small samples are free.If same as your requirements,we will just charge for mould to support.

Q3:If products are not to requirement,how can you do?

We will try our every best to solove it.Meeting your requirement is our mission.

Q4:What's the lead time?

Normally,for standard items,will ship within 1-10 days.For mass production order,we will finish within 30 working days after we receive payment.

Q5:Payment terms:

We can negotiate.

We can send you samples or sample material for you to check or test.Let our physical samples speak loudly.

Q2:Are these samples free of charge?

Some standard small samples are free.If same as your requirements,we will just charge for mould to support.

Q3:If products are not to requirement,how can you do?

We will try our every best to solove it.Meeting your requirement is our mission.

Q4:What's the lead time?

Normally,for standard items,will ship within 1-10 days.For mass production order,we will finish within 30 working days after we receive payment.

Q5:Payment terms:

We can negotiate.