Exhibition

Long Term Grain Storage: How Long Can Grains Be Stored? (Wheat, Corn & Quinoa)

Whether you grow your grains or buy them in bulk, the correct long term grain …

Custom High Wear-resistant Al2O3 Zirconia Si3N4 Ceramic Rod

Product Description

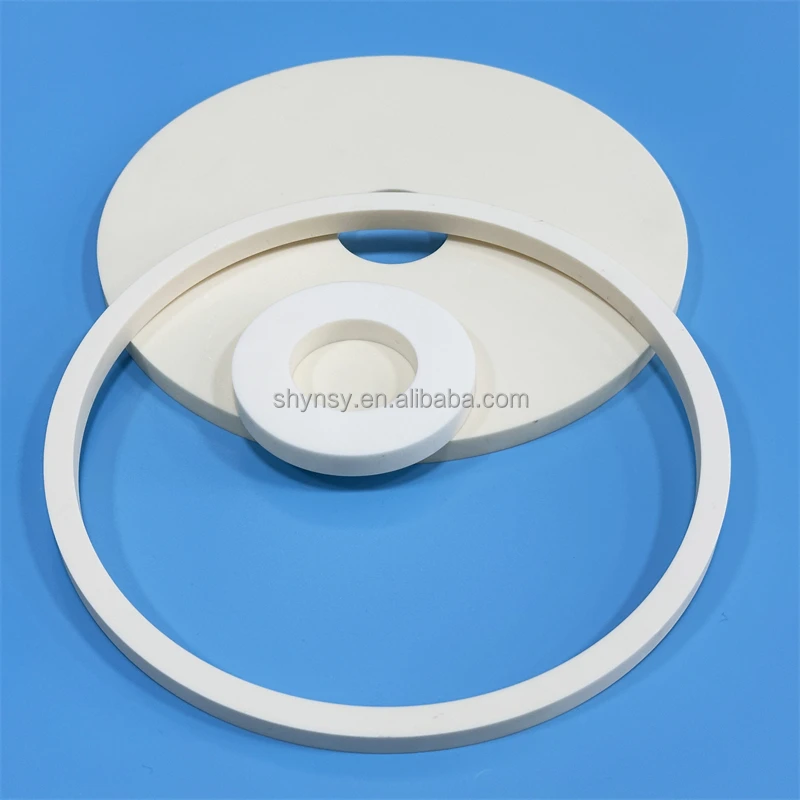

Precision ceramic processing parts

Alumina ceramic is kind of structural ceramics, with insulation resistance, voltage resistance, high strength, good thermal conductivity, dielectric loss, stable electrical performance characteristics. Used in electronic ceramic substrates, ceramic electrical insulation, vacuum devices, devices porcelain, spark plugs and other products. We can make the part by hot injection pressing, dry pressing, 200T isostatic pressing and extrusion productive technology etc.

Zirconia ceramics is a kind of ceramic material based on zirconia.In terms of structural ceramics, zirconia is different from traditional ceramics. Zirconia has very high strength, wear resistance and flexibility, which far exceeds most other technical ceramics. Zirconia is a very strong industrial ceramic with excellent properties in hardness, fracture toughness and corrosion resistance. Compared with metals,in daily use special ceramics have the characteristics of non-rusting, non-magnetic, wear resistance and insulation, so zirconia ceramics have high toughness, high bending strength and high wear resistance, as well as excellent thermal insulation and Coefficient of thermal expansion similar to steel, so it is widely used in the field of structural ceramics.

Silicon nitride has very good comprehensive properties, such as very high strength, toughness, excellent

abrasion resistance and chemical resistance, high thermal conductivity and low thermal expansion coefficient,

which make it have good thermal shock resistance and stable performance. Due to these good comprehensive properties and relatively low density, silicon nitride materials can meet the highest quality requirements in applications. Typical applications include:

High-grade refractory crucible

Bearings and wire drawing dies

Welding nozzle and positioning pin

Cutting tools

Thermocouple protective sleeve

abrasion resistance and chemical resistance, high thermal conductivity and low thermal expansion coefficient,

which make it have good thermal shock resistance and stable performance. Due to these good comprehensive properties and relatively low density, silicon nitride materials can meet the highest quality requirements in applications. Typical applications include:

High-grade refractory crucible

Bearings and wire drawing dies

Welding nozzle and positioning pin

Cutting tools

Thermocouple protective sleeve

Ceramic Performance Table | ||||||

Properties | 99% Al₂O₃ | 95% Al₂O₃ | Zirconia | |||

Density (g/cm3) | 3.85 | 3.6 | 6 | |||

Working Temperature℃ | 1700 | 1680 | 1600 | |||

Rupture Strength 4pt | >3500 | 2900 | 11000 | |||

Compressive Strength (Kgf/cm³) | 30000 | 25000 | 25000 | |||

Max Use Temperature℃ | 1500 | 1400 | 1600 | |||

Thermal Expansivity | 8 | 7.8 | 10 | |||

10-6/℃ | ||||||

0-1000℃ | ||||||

Thermal Impact Resistance T(℃) | 200 | 220 | 350 | |||

Thermal Conductivity (W/m.k) | 31 | 22 | 3 | |||

Volume Resistance (Ω.cm) | >10¹² | >10¹² | >10¹² | |||

Insulation Failure Strength(KT/m) | 18 | 16 | 15 | |||

Dielectric Coefficient(1MHz(E)) | 9.2-10.5 | 9.0-10 | 12.5 | |||

Si3n4 | ||||

Item | Unit | Value | ||

Purity | % | >91 | ||

Density | g/cm3 | ≥3.23 | ||

Heat-resistant temperature | C | 1300 | ||

High temperature resistivity | Ω·m | 1014 | ||

Thermal conductivity (normal temperature) | W/(m·k) | 18 | ||

Heat conductivity 1000C | W/(m·k) | 25 | ||

Vickers hardness | HV10 | 1300-1600 | ||

Flexural strength | kg/cm2 | 700-900 | ||

Rupture strength | kg/cm2 | ≥450 | ||

Coefficient of linear expansion | 10-6/K | 2.8-3.2 | ||

Recommend Products

Company Profile

Products Description

Certifications

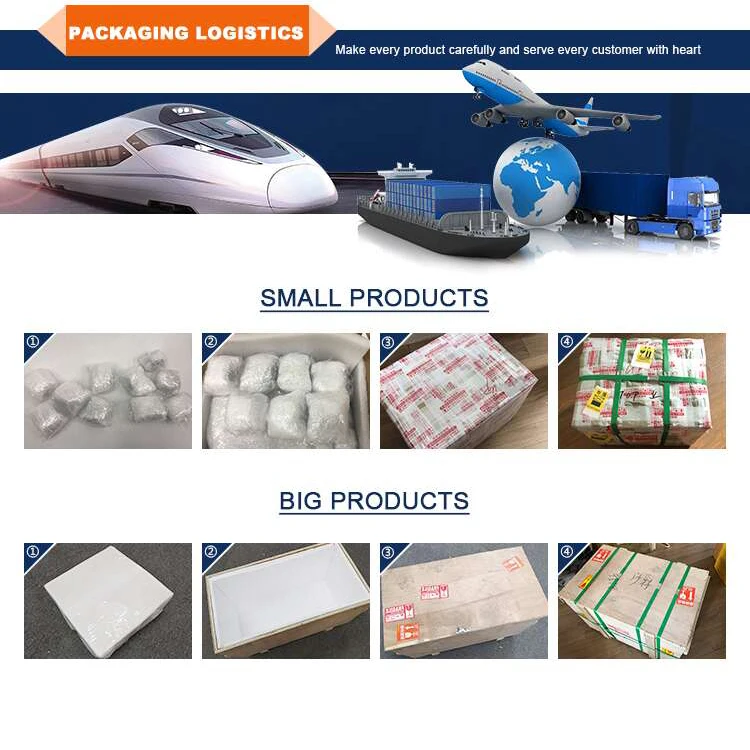

Way of shipping

Our Advantages

FAQ

Q1: How can know your quality?

We can send you samples or sample material for you to check or test.Let our physical samples speak loudly.

Q2:Are these samples free of charge?

Some standard small samples are free.If same as your requirements,we will just charge for mould to support.

Q3:If products are not to requirement,how can you do?

We will try our every best to solove it.Meeting your requirement is our mission.

Q4:What's the lead time?

Normally,for standard items,will ship within 1-10 days.For mass production order,we will finish within 30 working days after we receive payment.

Q5:Payment terms:

We can negotiate.

We can send you samples or sample material for you to check or test.Let our physical samples speak loudly.

Q2:Are these samples free of charge?

Some standard small samples are free.If same as your requirements,we will just charge for mould to support.

Q3:If products are not to requirement,how can you do?

We will try our every best to solove it.Meeting your requirement is our mission.

Q4:What's the lead time?

Normally,for standard items,will ship within 1-10 days.For mass production order,we will finish within 30 working days after we receive payment.

Q5:Payment terms:

We can negotiate.