Exhibition

Long Term Grain Storage: How Long Can Grains Be Stored? (Wheat, Corn & Quinoa)

Whether you grow your grains or buy them in bulk, the correct long term grain …

NSiC Silicon Nitride ( Si3n4 ) Bonded Silicon Carbide ( SiC ) Ceramic Thermocouple Protection Tube for Sheath

Product Description

Silicon nitride combined with silicon carbide products is a structural ceramic material. High-purity SIC and Si

NSiC has higher flexural strength and excellent oxidation resistance than RSiC products. The maximum operating temperature is1500. In addition to its own structural characteristics, NSiC products also have good wear resistance and corrosion resistance to metal solutions, so NSiC products can directly contact aluminum, zinc, copper, and magnesium solutions, and NSiC protection tube was successfully used for temperature measurement.

NSiC has characteristics that other refractory materials do not have, such as high temperature resistance to bending, excellent high load loading and wear resistance.

powder are used as raw materials, and the body is formed by grouting and pressing, and is sintered by nitriding reaction. Silicon nitride and silicon carbide products include thin wall slabs, round tubes, burners and a variety of complex heterosexual products, as well as beams of various cross sections.

NSiC has higher flexural strength and excellent oxidation resistance than RSiC products. The maximum operating temperature is1500. In addition to its own structural characteristics, NSiC products also have good wear resistance and corrosion resistance to metal solutions, so NSiC products can directly contact aluminum, zinc, copper, and magnesium solutions, and NSiC protection tube was successfully used for temperature measurement.

NSiC has characteristics that other refractory materials do not have, such as high temperature resistance to bending, excellent high load loading and wear resistance.

Item | Unit | Data |

Bulk density | g/cm3 | 2.75-2.82 |

Porosity | % | 10-12 |

Compressive strength | MPa | 600-700 |

Flexural strength | MPa | 160-180 |

Young's modulus | Gpa | 220-260 |

Thermal Conductivity | W/MK | 15 |

Thermal expansion coefficient: 20-1000 ℃ | 10-6K-1 | 5.0 |

Maximum use temperature | C | 1500 |

SiC | % | 60-80 |

Silicon nitride | % | 20-40 |

Applications:

Silicon nitride and silicon carbide beams have excellent high-temperature flexural strength, creep resistance

and oxidation resistance; mainly used in sanitary ceramics, high-voltage electrical porcelain, filters, quartz

crucibles; shed plates and fish-shaped plates which are widely used in daily-use ceramic Industry; protection

tube is used for temperature measurement in various industries; special-shaped products and burner sleeves

are widely used in various kiln and mechanical engineering.

Recommend Products

Company Profile

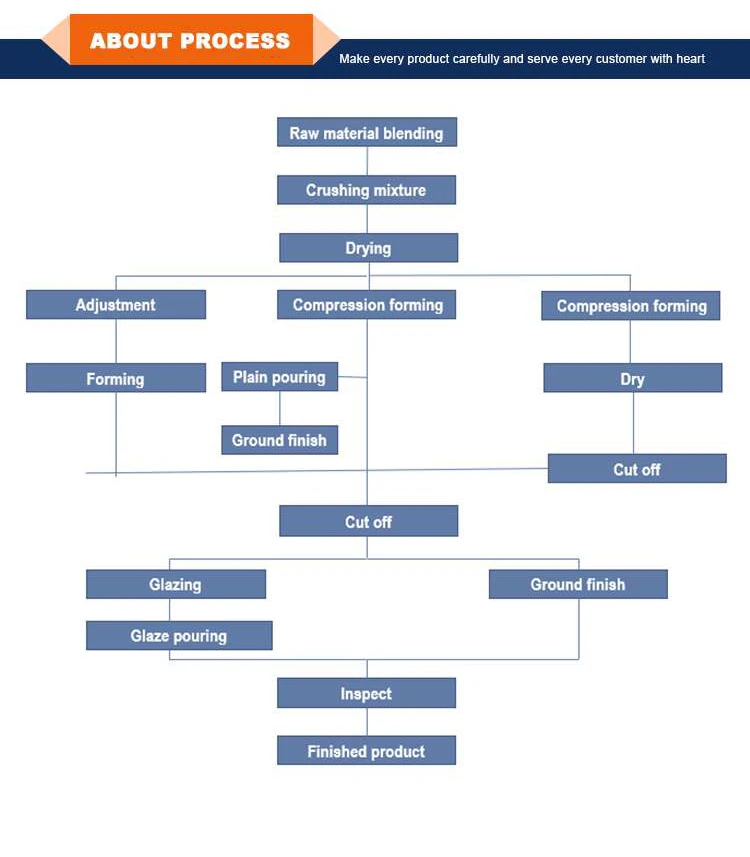

Products Description

Certifications

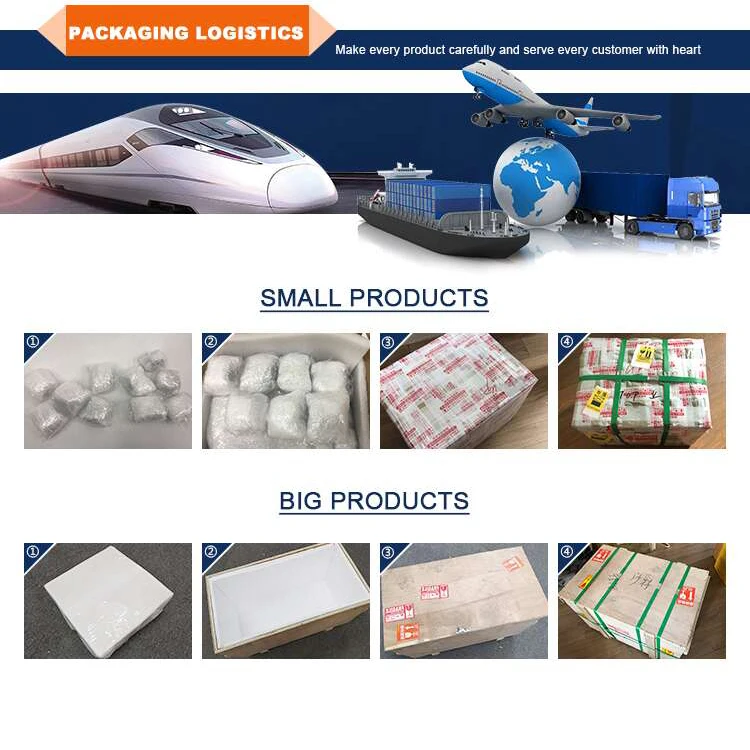

Way of shipping

Our Advantages

FAQ

Q1: How can know your quality?

We can send you samples or sample material for you to check or test.Let our physical samples speak loudly.

Q2:Are these samples free of charge?

Some standard small samples are free.If same as your requirements,we will just charge for mould to support.

Q3:If products are not to requirement,how can you do?

We will try our every best to solove it.Meeting your requirement is our mission.

Q4:What's the lead time?

Normally,for standard items,will ship within 1-10 days.For mass production order,we will finish within 30 working days after we

receive payment.

Q5:Payment terms:

We can negotiate.

We can send you samples or sample material for you to check or test.Let our physical samples speak loudly.

Q2:Are these samples free of charge?

Some standard small samples are free.If same as your requirements,we will just charge for mould to support.

Q3:If products are not to requirement,how can you do?

We will try our every best to solove it.Meeting your requirement is our mission.

Q4:What's the lead time?

Normally,for standard items,will ship within 1-10 days.For mass production order,we will finish within 30 working days after we

receive payment.

Q5:Payment terms:

We can negotiate.