Exhibition

Long Term Grain Storage: How Long Can Grains Be Stored? (Wheat, Corn & Quinoa)

Whether you grow your grains or buy them in bulk, the correct long term grain …

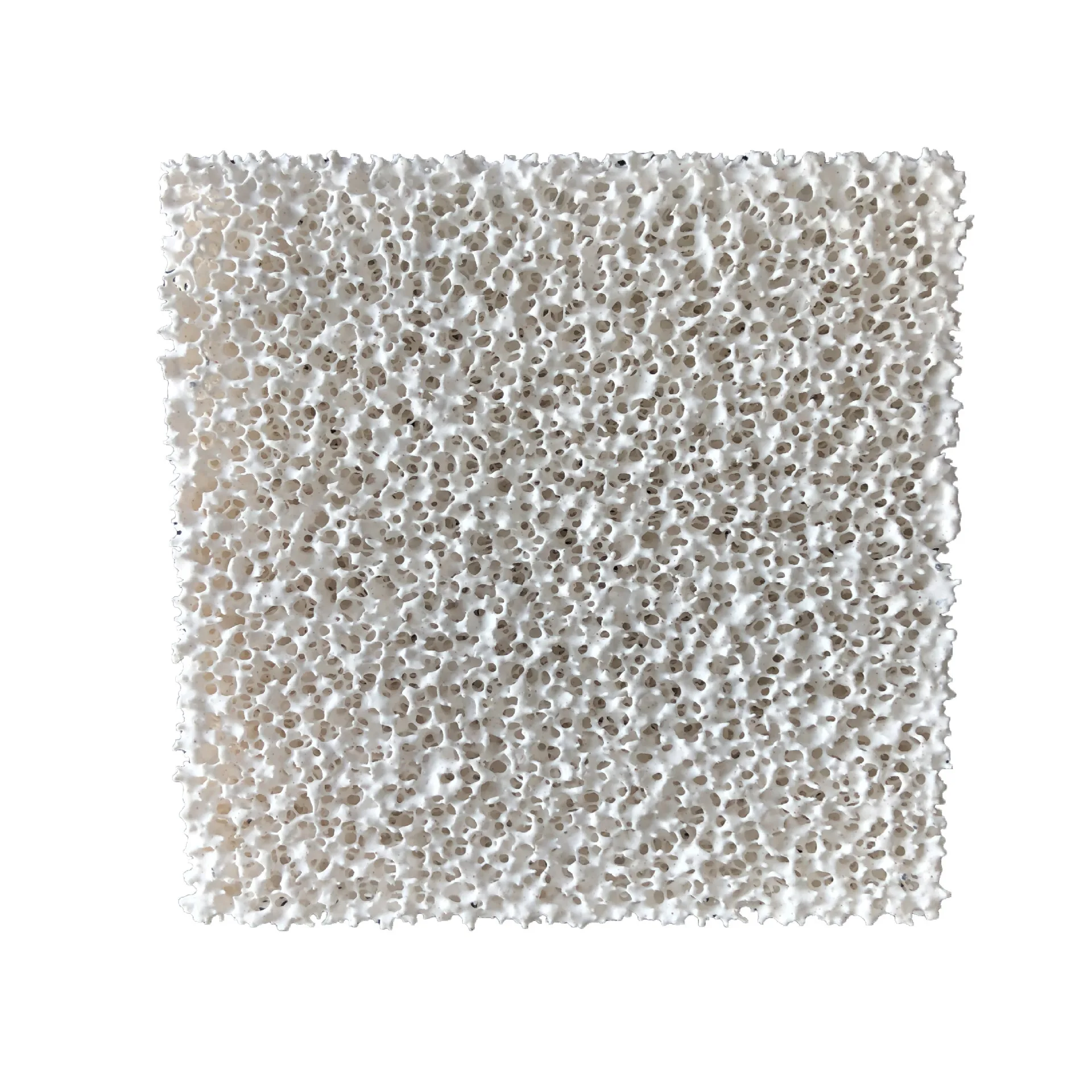

Pure Al2o3 Aluminum Oxide Ceramic Foam High Temperature Insulation for Aluminium Casting

Product Description

Alumina foam ceramic filter is made of high quality and high purity alumina. It is made of unique formula and

advanced environmental protection technology.

It has uniform three-dimensional network structure, high strength, stable texture, no slag,

high temperature resistance and thermal shock resistance. Strong and excellent performance. Mainly used

high temperature resistance and thermal shock resistance. Strong and excellent performance. Mainly used

in the purification process of aluminum and aluminum alloy production, also applied to various gas-solid,

liquid-solid separation media,catalyst carrier,burner and sound-absorbing environmental protection; filter can

make aluminum liquid more evenly filled In the cavity, the molten metal has a high turbulence tendency during

casting, and is finally converted into a very stable laminar flow through the turbulent flow of the three-

dimensional pore structure. The laminar flow has better filling of the cavity, which reduces the

impact corrosion of the metal solution on the casting cavity, and significantly reduces the scrap rate,

impact corrosion of the metal solution on the casting cavity, and significantly reduces the scrap rate,

reduces the production cost, and improves the labor productivity.

Material:alumina

Hole density: 10~50 PPI

Bulk density (g/cm3):0.3~0.5

Porosity(%):≥80

Normal temperature compressive strength (MPa) ≥0.8

Thermal shock resistance (time / 1100 C ~ room temperature):3

Size:

Length/diemater: 40~200mm

Width/diameter: 40~200

Thickness: 15~30mm

Can also be customized.

Working temperature: ≤900 C

Advantages:

1.Filter out the inclusions in the casting, reduce the gas in the casting, reduce the degree of turbulence during

Material:alumina

Hole density: 10~50 PPI

Bulk density (g/cm3):0.3~0.5

Porosity(%):≥80

Normal temperature compressive strength (MPa) ≥0.8

Thermal shock resistance (time / 1100 C ~ room temperature):3

Size:

Length/diemater: 40~200mm

Width/diameter: 40~200

Thickness: 15~30mm

Can also be customized.

Working temperature: ≤900 C

Advantages:

1.Filter out the inclusions in the casting, reduce the gas in the casting, reduce the degree of turbulence during

the flow filling of the metal, reduce the surface defects in the casting, and significantly reduce the rejection

rate of the casting.

2.Improve the fluidity of molten metal, increase the filling ability and shrinkage ability of the casting, improve

2.Improve the fluidity of molten metal, increase the filling ability and shrinkage ability of the casting, improve

the surface finish of the casting, increase the compression seal of the casting, enhance the elongation and

tensile strength, and improve the surface quality and mechanical properties of the casting.

3.It has very high temperature working strength,chemical stability,thermal shock resistance and resistance to

3.It has very high temperature working strength,chemical stability,thermal shock resistance and resistance to

metal liquid flow impact. High chemical stability makes it not affected by the acidity and alkalinity of the

molten metal and does not change the chemical composition of the molten metal. There is no slag dropping

or cracking in the work, which ensures the filtration quality of molten metal and the stability of chemical

composition.

4.Has a large metal flow rate, and the flow rate is stable (different from the straight hole ceramic filter, the flow rate gradually decreases with the increase in the number of captured impurities). Its filtering effect is much higher

4.Has a large metal flow rate, and the flow rate is stable (different from the straight hole ceramic filter, the flow rate gradually decreases with the increase in the number of captured impurities). Its filtering effect is much higher

than that of other filtering elements.

5.It is resistant to the corrosion of liquid aluminum and its alloys. It does not contain phosphorus. It is

5.It is resistant to the corrosion of liquid aluminum and its alloys. It does not contain phosphorus. It is

environmentally friendly to purify aluminum liquid, improve the quality of aluminum, reduce defects, reduce

the rate of defective products,reduce costs, increase production efficiency, and be simple and flexible to use.

6.With very high dimensional accuracy, it can be used in the production line for automatic filter placement.

Item | AL2O3 |

Hole density PPI | 10~50 |

Bulk density g/cm3 | 0.3~0.5 |

Porosity % | ≥80 |

Compressive strength at room temperature MPa | ≥0.8 |

Thermal shock resistance (time/1100C~ normal temperature) | 3 |

Length/od mm | 40~200 |

Width/od mm | 40~200 |

Thickness mm | 15~30 |

Working temperature C | ≤900 |

Application | cast aluminum parts |

Other application | Gas-solid / liquid-solid separation media, tail gas filtration, chemical fillers, catalyst carriers |