Exhibition

Long Term Grain Storage: How Long Can Grains Be Stored? (Wheat, Corn & Quinoa)

Whether you grow your grains or buy them in bulk, the correct long term grain …

Silicon Carbide Alumina zirconia zr ceramic foam filters Porous ceramic filter foam for casting

Product Description

Zirconia Ceramic Foam Filters:

Zirconia foam ceramic filter is made of high-quality and high-purity zirconia, using unique formula and advanced environmental protection technology. It has a uniform three-dimensional network structure, high strength, stable texture, no slag dropping, high temperature resistance, and thermal shock resistance ect .

Excellent performance: Suitable for purification and filtration of stainless steel, carbon steel, copper castings and other high temperature alloy solutions below 1700C. Can filter non-metal slag inclusions and slags as small as micrometers, making the surface of steel castings smoother and reducing machining losses; the filter can make the molten steel fill the cavity more uniformly, and the molten metal has a higher turbulence during pouring tendency, the turbulent flowing through the three-dimensional pore structure is finally converted into a very stable laminar flow. Laminar flow fills the cavity better, which reduces the impact corrosion of the metal solution on the casting cavity, and significantly reduces the reject rate, reduces production costs, and improves labor productivity.

Zirconia foam ceramic filter is made of high-quality and high-purity zirconia, using unique formula and advanced environmental protection technology. It has a uniform three-dimensional network structure, high strength, stable texture, no slag dropping, high temperature resistance, and thermal shock resistance ect .

Excellent performance: Suitable for purification and filtration of stainless steel, carbon steel, copper castings and other high temperature alloy solutions below 1700C. Can filter non-metal slag inclusions and slags as small as micrometers, making the surface of steel castings smoother and reducing machining losses; the filter can make the molten steel fill the cavity more uniformly, and the molten metal has a higher turbulence during pouring tendency, the turbulent flowing through the three-dimensional pore structure is finally converted into a very stable laminar flow. Laminar flow fills the cavity better, which reduces the impact corrosion of the metal solution on the casting cavity, and significantly reduces the reject rate, reduces production costs, and improves labor productivity.

Material data:

Al2O3 | MgO | SiO2 | ZrO2 | Fe2O3 |

≤1.8% | ≥3.0% | ≤0.5% | ≥ 94.00% | ≤0.10% |

Item | Zro2 | ||

Hole density PPI | 10~30 | ||

Bulk density g/cm3 | 0.7~0.85 | ||

Porosity % | ≥80 | ||

Compressive strength at room temperature MPa | ≥1.2 | ||

Thermal shock resistance (time/1350C~ normal temperature) | 3 | ||

Standard size | Length/OD mm | 40~200 | |

Width/OD mm | 40~200 | ||

Thickness(mm) | 15~30 | ||

We can made to order | |||

Working temperature C | ≤1700 | ||

Company Profile

Products Description

Certifications

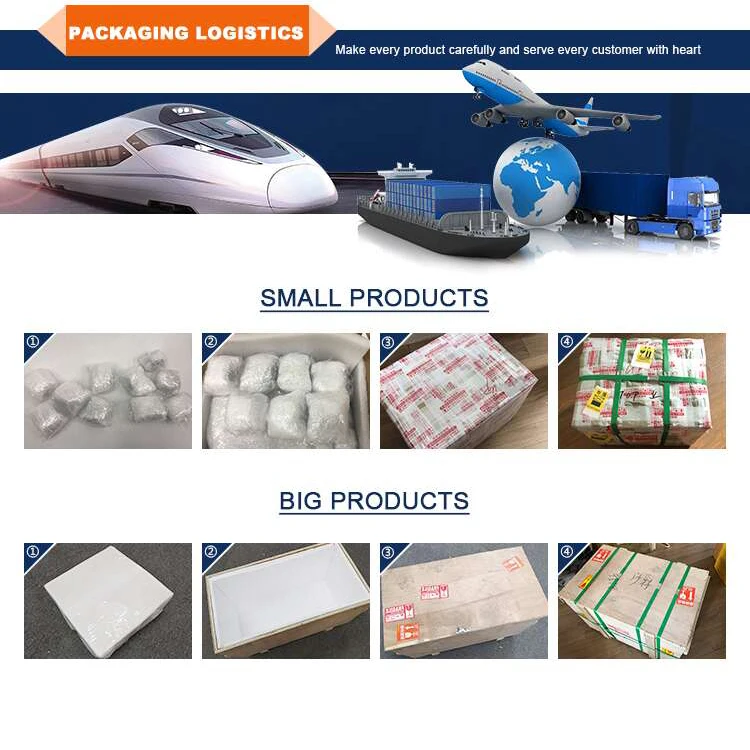

Way of shipping

Our Advantages

FAQ

Q1: How can know your quality?

We can send you samples or sample material for you to check or test.Let our physical samples speak loudly.

Q2:Are these samples free of charge?

Some standard small samples are free.If same as your requirements,we will just charge for mould to support.

Q3:If products are not to requirement,how can you do?

We will try our best to solove.Meeting your requirement is our mission.

Q4:What's the lead time?

Normally,for standard items,will ship within 1-10 days.For mass production order,we will finish within 30 working days after we

receive payment.

Q5:Payment terms:

We can negotiate.

We can send you samples or sample material for you to check or test.Let our physical samples speak loudly.

Q2:Are these samples free of charge?

Some standard small samples are free.If same as your requirements,we will just charge for mould to support.

Q3:If products are not to requirement,how can you do?

We will try our best to solove.Meeting your requirement is our mission.

Q4:What's the lead time?

Normally,for standard items,will ship within 1-10 days.For mass production order,we will finish within 30 working days after we

receive payment.

Q5:Payment terms:

We can negotiate.